Charlie company uses a perpetual inventory system – Charlie Company’s adoption of a perpetual inventory system has revolutionized its inventory management practices. This advanced system offers real-time inventory visibility, enabling the company to optimize stock levels, reduce costs, and enhance operational efficiency.

The implementation of a perpetual inventory system requires careful planning and execution. Charlie Company meticulously followed the steps Artikeld in industry best practices, ensuring accuracy and efficiency in inventory tracking.

1. Perpetual Inventory System Overview

A perpetual inventory system is a method of tracking inventory levels on a continuous basis, updating the records each time an inventory transaction occurs. This differs from periodic inventory systems, which only update inventory records at specific intervals, such as monthly or quarterly.

Perpetual inventory systems provide real-time visibility into inventory levels, allowing businesses to better manage their inventory and reduce the risk of stockouts.

Some of the benefits of using a perpetual inventory system include:

- Improved accuracy: Perpetual inventory systems are more accurate than periodic systems because they are updated in real time.

- Reduced risk of stockouts: Perpetual inventory systems help businesses avoid stockouts by providing real-time visibility into inventory levels.

- Improved inventory management: Perpetual inventory systems help businesses better manage their inventory by providing detailed information about inventory levels, such as the location of each item and the number of units on hand.

However, there are also some limitations to using a perpetual inventory system:

- Increased cost: Perpetual inventory systems can be more expensive to implement and maintain than periodic systems.

- Increased complexity: Perpetual inventory systems can be more complex to implement and maintain than periodic systems.

- Increased risk of errors: Perpetual inventory systems are more susceptible to errors than periodic systems because they are updated more frequently.

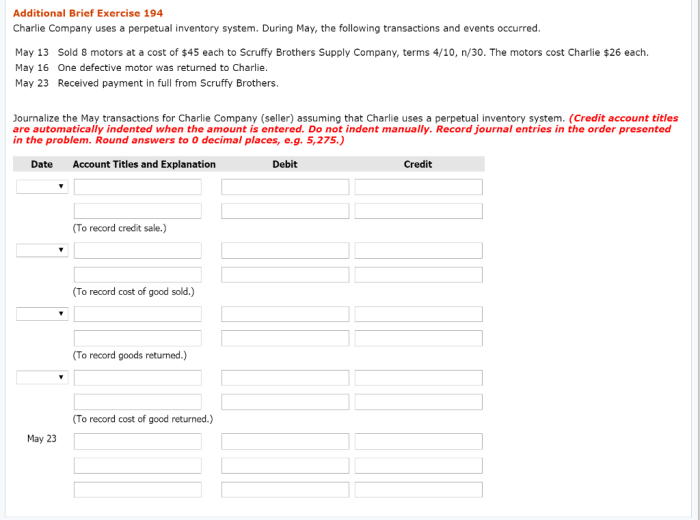

2. Implementation of Perpetual Inventory System: Charlie Company Uses A Perpetual Inventory System

Implementing a perpetual inventory system can be a complex process, but it can be done successfully by following these steps:

- Choose the right software: The first step is to choose the right software to manage your perpetual inventory system. There are many different software options available, so it is important to do your research and choose a software that meets your specific needs.

- Train your staff: Once you have chosen a software, you need to train your staff on how to use it. This training should include how to enter inventory transactions, how to update inventory levels, and how to generate inventory reports.

- Establish inventory control procedures: You need to establish inventory control procedures to ensure that your inventory is accurate and well-managed. These procedures should include how to receive inventory, how to store inventory, and how to ship inventory.

- Monitor your inventory levels: Once you have implemented a perpetual inventory system, you need to monitor your inventory levels on a regular basis. This will help you identify any potential problems, such as stockouts or overstocks.

Technology plays a vital role in managing perpetual inventory systems. Inventory management software can help businesses track inventory levels, update records in real time, and generate reports. Barcode scanners and RFID tags can also be used to improve the accuracy and efficiency of inventory management.

To maintain accuracy in perpetual inventory systems, it is important to follow best practices, such as:

- Using a reliable inventory management software

- Training staff on how to use the software correctly

- Establishing clear inventory control procedures

- Monitoring inventory levels on a regular basis

- Reconciling inventory records with physical inventory counts

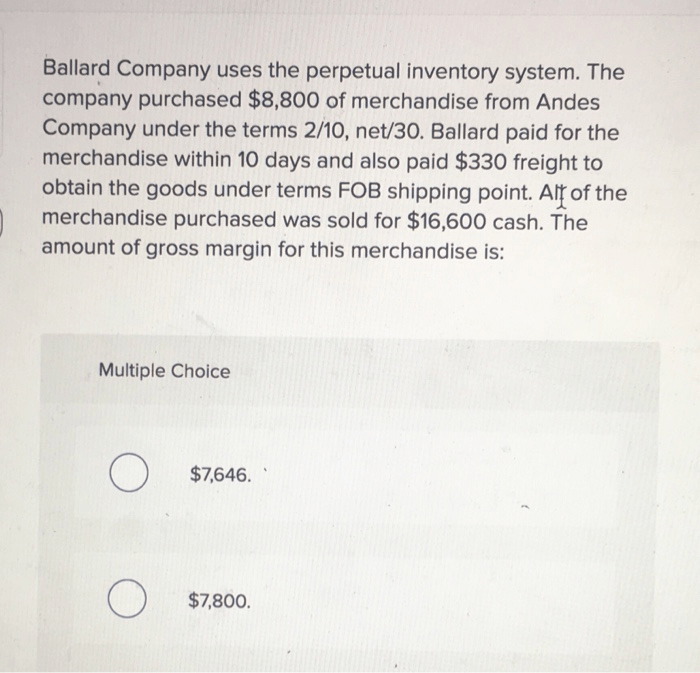

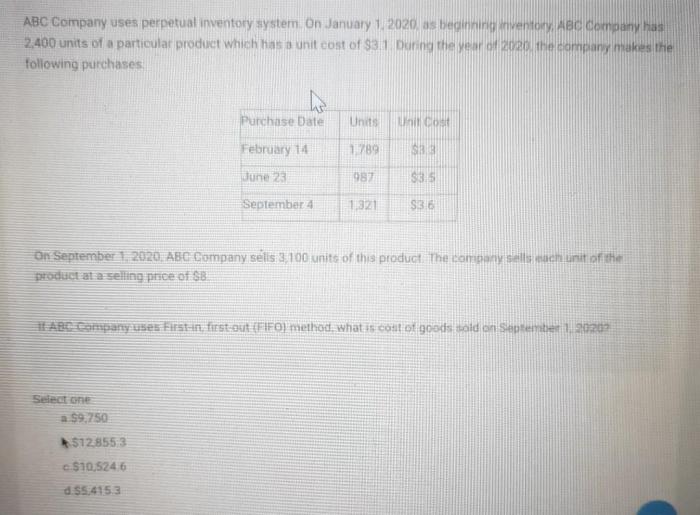

3. Inventory Valuation and Cost Flow Assumptions

Inventory valuation is the process of determining the value of inventory on hand. There are several different inventory valuation methods that can be used, including:

- First-in, first-out (FIFO): FIFO assumes that the oldest inventory is sold first. This method results in the highest cost of goods sold (COGS) and the lowest ending inventory value.

- Last-in, first-out (LIFO): LIFO assumes that the newest inventory is sold first. This method results in the lowest COGS and the highest ending inventory value.

- Weighted average: Weighted average assumes that all inventory is sold at an average cost. This method results in a COGS that is between the FIFO and LIFO COGS.

The cost flow assumption that a company uses can have a significant impact on its financial statements. For example, a company that uses FIFO will have a higher COGS and a lower ending inventory value than a company that uses LIFO.

This can affect the company’s net income and gross profit margin.

Detailed FAQs

What are the key benefits of using a perpetual inventory system?

Perpetual inventory systems provide real-time inventory visibility, enabling businesses to optimize stock levels, reduce costs, and enhance operational efficiency.

How does a perpetual inventory system differ from other inventory systems?

Perpetual inventory systems continuously track inventory levels as transactions occur, unlike periodic inventory systems that only update inventory records at specific intervals.

What are the challenges associated with implementing a perpetual inventory system?

Implementing a perpetual inventory system requires careful planning, accurate data entry, and regular reconciliation to ensure accuracy.